Forge Ahead:

Next-Gen TimeLine ERP

for Indian Foundries

Specialized ERP Solutions for the Foundry Industry and Casting Industry

TimeLine Foundry ERP is designed to meet the unique challenges of Indian foundry operations. From small-scale units to large manufacturers, Our solution scales to fit your needs.

TimeLine Foundry ERP

Key Features

Comprehensive

Process Integration

Seamlessly manage your entire foundry operation from melting to shipping. Our integrated approach ensures smooth workflow and enhanced productivity.

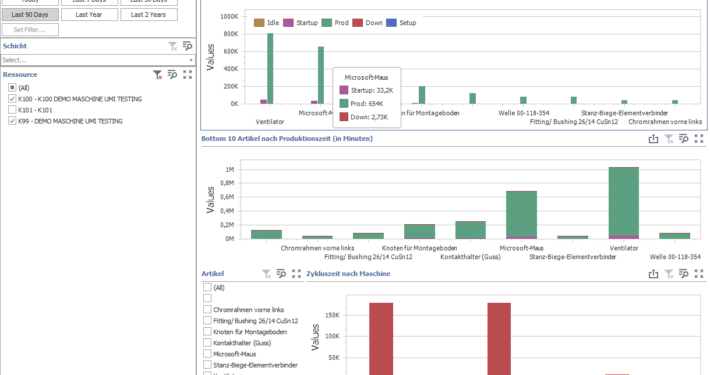

Real-time

Insights

Get instant visibility into your production processes, quality control, and inventory levels. Make informed decisions with up-to-the-minute data at your fingertips.

Boost Efficiency,

Reduce Costs

We helps you streamline operations, minimize waste, and optimize resource utilization. Our clients report an significant increase in operational efficiency within a short time of implementation.

Expert

Local Support

Our dedicated Indian support team ensures you get the assistance you need, when you need it. With offices in Ahmedabad, we’re always just a call away.

Why Choose Timeline Foundry ERP?

- 30+ years of global foundry industry experience

- Robust data security measures.

- Industry-proven features co-designed with foundries

- Dedicated R&D team constantly innovating for the casting sector

- Scalable and customizable to individual requirements.

- Seamless integration of inventory, warehouse management, and production modules.

- Tailored ERP software for the casting industry, die casting, and steel manufacturing

- Flexible deployment options: on-premise or cloud-based.

- Easy to customize thanks to the integrated development tool.

Ready to Transform Your Foundry?

Take the first step towards optimizing your foundry operations. Contact our Indian team of experts today for a free demonstration and consultation.

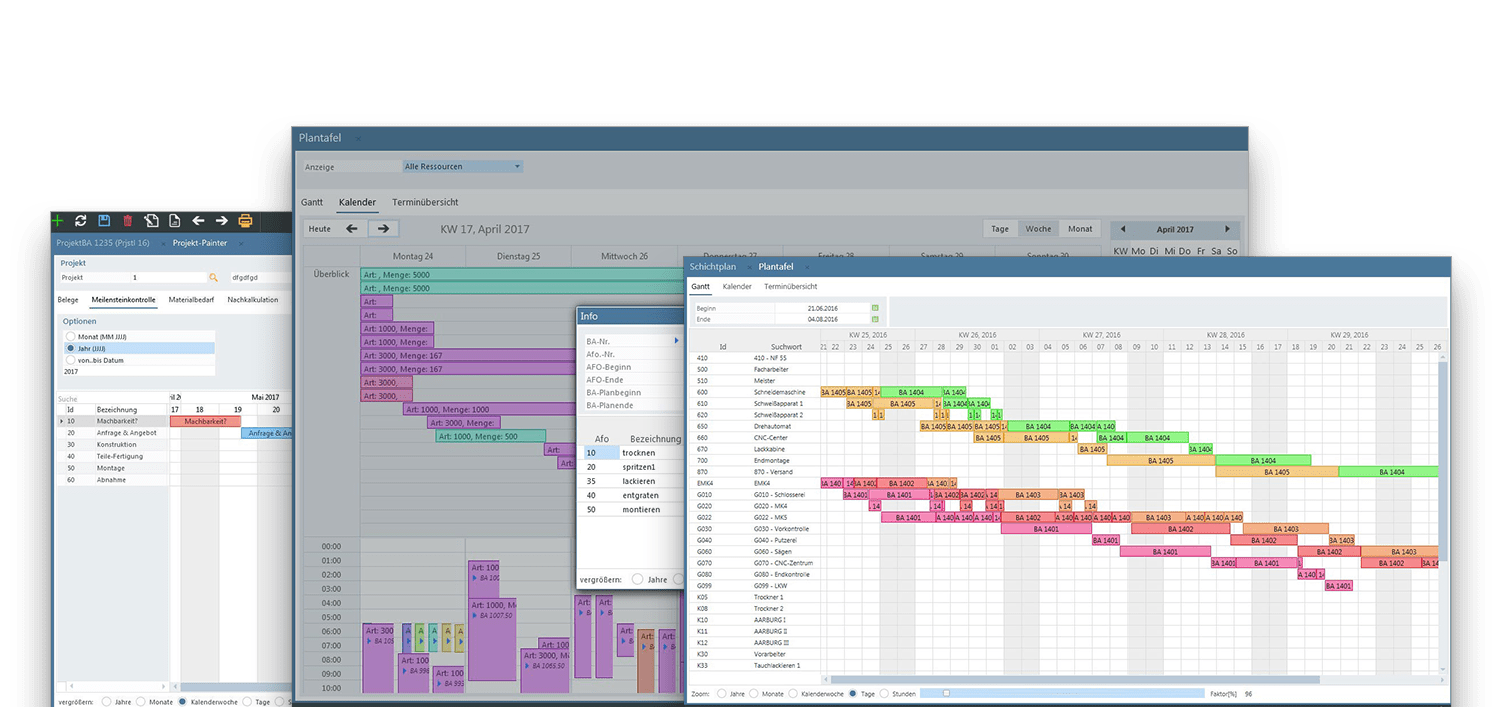

Production Planning

Streamlined Planning for Optimal Efficiency

TimeLine Foundry ERP is equipped with Foundry Features Like:

- Optimizes Production Planning in automotive casting operations.

- Advanced Algorithms optimize resource allocation,

- Minimize waste

- Maximize output

- Strengthen & Optimize Inventory Control

- Reduce Downtime

- Reduce Opportunity loss

From melting to final inspection, Timeline Foundry ERP ensures smooth workflows and timely deliveries.

Uncompromising Quality Management

In the automotive industry, quality is non-negotiable. Our ERP system incorporates robust quality control measures at every stage of the casting process. From raw material inspection to final product testing, TimeLine ERP ensures that every component meets the stringent standards of the automotive sector.

IoT Integration for Real-Time Insights

Harness the power of the Internet of Things (IoT) in your foundry. TimeLine Foundry ERP seamlessly integrates with sensors and smart devices throughout your facility, providing real-time data on production rates. Make informed decisions instantly and prevent costly downtime.

Melting Department Optimization

Maximize efficiency in your melting department. Our system provides precise control over furnace operations, alloy compositions, and energy consumption. Reduce costs and improve consistency in your foundry’s most critical area.

Advanced Mould Management

Our system provides detailed tracking and control throughout the entire mould lifecycle. With TimeLine ERP, you can maintain a detailed mould inventory, tracking the location, status, and usage history of each mould.

Key Functionalities of TimeLine Foundry ERP

Alloy & Energy Surcharge Management

- Dynamic alloy and energy surcharge management

- Individually selectable calculation times

- Configurable limits and automated changeover module

Tool & Resource Management

- Management of tools, tool life, blocking status, and associated documents

- Cost collection for toolmaking orders

- Handling of external toolmaking delivery notes and service orders

Production Management

- Real-time production feedback via manual input or BDE terminals

- Centralized production monitoring dashboard

- Integrated management of technical drawings

- Simultaneous post-calculation within production orders

- Coupled production order handling

Costing & Calculation

- Pre-calculation for virtual and existing items

- Volume-based and margin-based costing

- Contribution margin and profitability analysis

- Surcharge and overhead calculations

- Automatic conversion of pre-calculations into sales offers

Advanced Planning & Scheduling (APS)

- Graphical planning interface with automated and fine planning

- Separation into planning groups with multiple capacity levels

- Integrated APS run for optimized planning

- ATP (Available-to-Promise) determination for sales and operations planning

Quality Management

- Integrated inspection planning (production-related & incoming goods)

- Test equipment management with capability analysis

- Creation of certificates, inspection reports, and control charts

- Inspection monitor with manual and terminal-based data entry

Ready to elevate your casting processes to the next level?

Download Your Free Brochure Now

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationContact Us

We would love to speak with you.

Feel free to reach out using the form below.

You can also call us or send us a WhatsApp:

+91 91526 59599